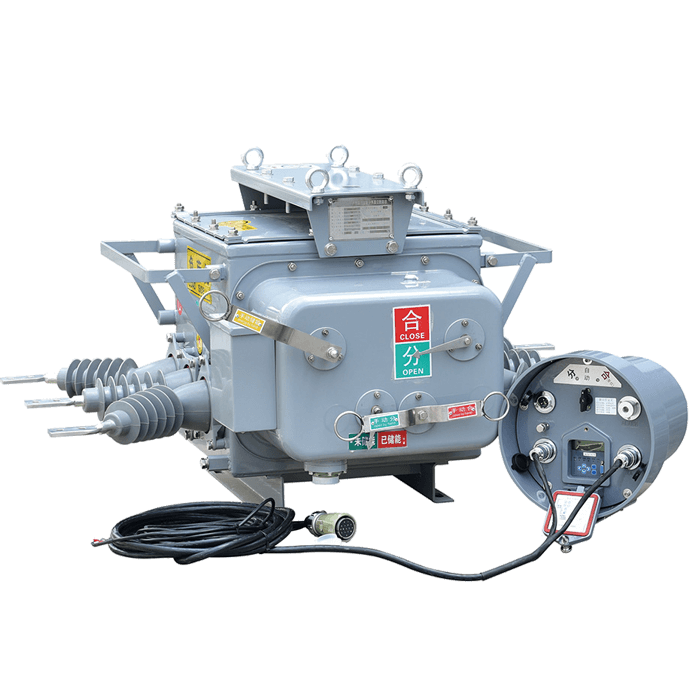

Working principle of vacuum circuit breaker

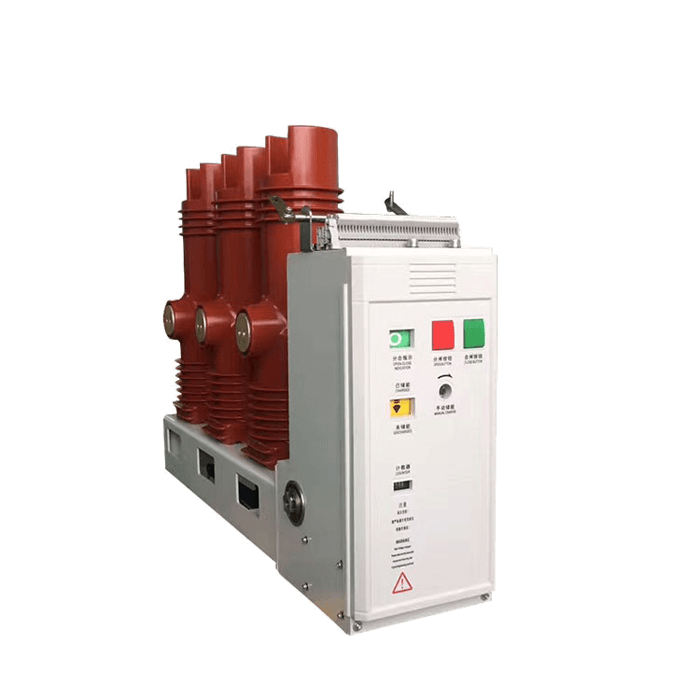

"Vacuum circuit breaker" is named because both the arc extinguishing medium and the insulating medium of the contact gap after arc extinguishing are high vacuum; it has the advantages of small size, light weight, suitable for frequent operation, and no need for maintenance for arc extinguishing. The application in the power grid is more popular. Vacuum circuit breaker is an indoor power distribution device in a 3-10kV, 50Hz three-phase AC system. It can be used for protection and control of electrical equipment in industrial and mining enterprises, power plants, and substations. In the places of maintenance and frequent operation, the circuit breaker can be configured in the middle cabinet, double-layer cabinet and fixed cabinet to control and protect high-voltage electrical equipment.

Working principle of vacuum circuit breaker

When the dynamic and static contacts of the vacuum circuit breaker are opened under the action of the operating mechanism, an arc is generated between the contacts, and the surface of the contacts volatilizes steam at high temperature. Magnetic field, the arc moves rapidly along the tangential direction of the contact surface under the action of this magnetic field, and part of the metal vapor is condensed on the metal cylinder (shield), the arc is extinguished when it naturally crosses zero, and the dielectric strength between the contacts is rapid. recover.

1. Closing process: When the closing coil of the operating mechanism is energized, the closing iron core is sucked in, and the movable conductive rod of the vacuum interrupter is moved through the arm and the connecting rod to close the circuit breaker.

2. Opening process: When the opening coil of the operating mechanism is energized, the opening iron core is sucked and closed, so that the lock is released, and the open circuit is quickly broken under the action of the opening spring.

3. Arc extinguishing process: There are spiral grooves on the dynamic and static contacts of the vacuum circuit breaker, so that a transverse magnetic field is applied to the axial direction of the arc. Rotate to avoid overheating of the face contacts.

The vacuum circuit breaker utilizes that when the current in the high vacuum flows through the zero point, the plasma rapidly diffuses and extinguishes the arc to complete the purpose of cutting off the current.

Action principle

1. Energy storage process

When the energy storage motor 14 is connected to the power supply, the motor drives the eccentric wheel to rotate, and the roller 10 close to the eccentric wheel drives the arm 9 and the connecting plate 7 to swing, pushes the energy storage pawl 6 to swing, and makes the ratchet wheel 11 rotate. When the pin on the ratchet wheel 11 is in contact with the plate of the energy storage sleeve 32, the two move together to elongate the closing spring 21 hanging on the energy storage sleeve 32. The energy storage sleeve 32 is fixed by the positioning pin 13 to maintain the energy storage state. At the same time, the crank arm on the energy storage sleeve 32 pushes the travel switch 5 to cut off the power supply of the energy storage motor 14, and the energy storage pawl is lifted, and the ratchet wheel is lifted. Reliable disengagement.

2. The closing operation process

When the mechanism receives the closing signal (the switch is off and the energy is stored), the iron core of the closing electromagnet 15 is sucked and moved downward, and the positioning member 13 is pulled to rotate counterclockwise, the energy storage maintenance is released, and the switch is closed. The spring 21 drives the energy storage sleeve 32 to rotate counterclockwise, and the cam presses the transmission sleeve 30 to drive the connecting plate 29 and the rocker arm 27 to move, so that the rocker arm 27 buckles the half shaft 25, and the mechanism is in the closed state. At this time, the interlocking device 28 locks the positioning member, so that the positioning cow cannot rotate counterclockwise, so as to achieve the purpose of linking the mechanism and ensure that the mechanism cannot be closed at the closing position.

3. Opening operation process

After the circuit breaker is closed, the opening electromagnet receives the signal, the iron core is sucked in, and the ejector rod in the opening release 19 moves upward, which makes the tripping shaft 16 rotate, drives the ejector rod 18 to move upward, and pushes the bent plate. 26 and drive the half shaft 25 to rotate counterclockwise. The half shaft 25 and the rocker arm 27 are unbuckled, and under the action of the opening spring, the circuit breaker completes the opening operation.