HV load break switch: Breaking Capability Assessment

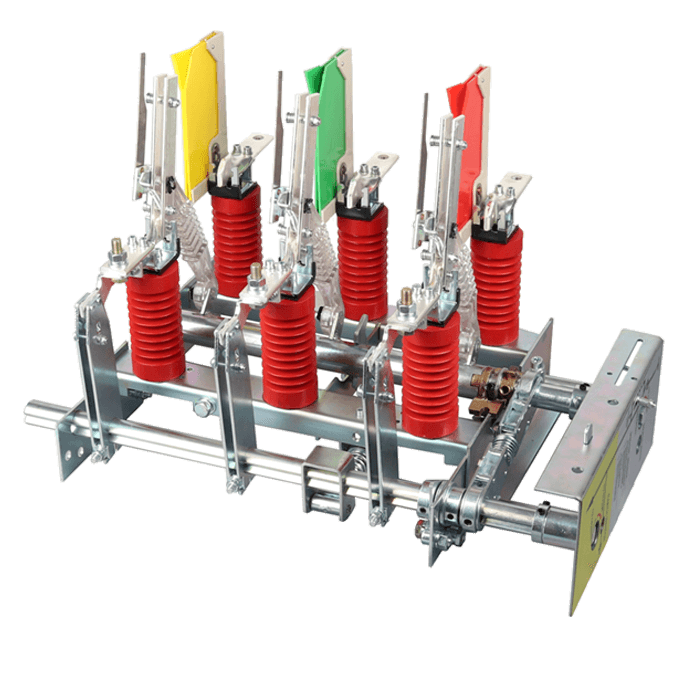

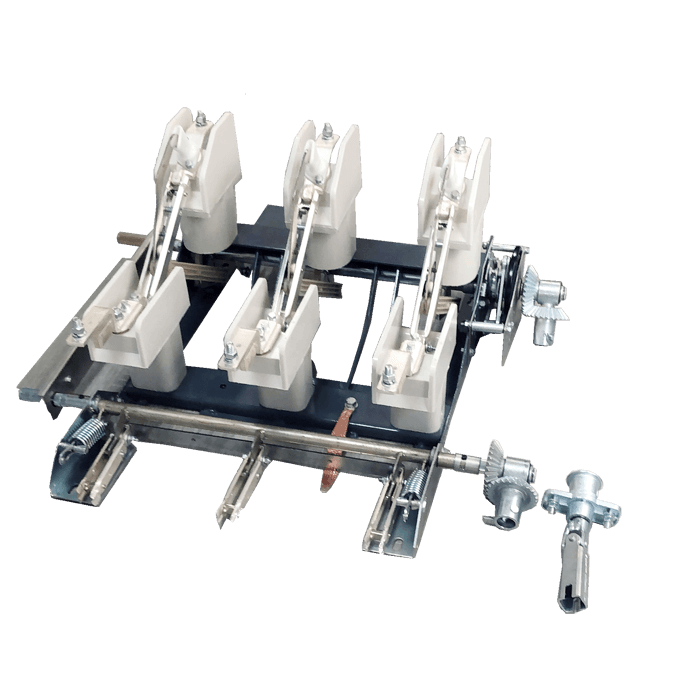

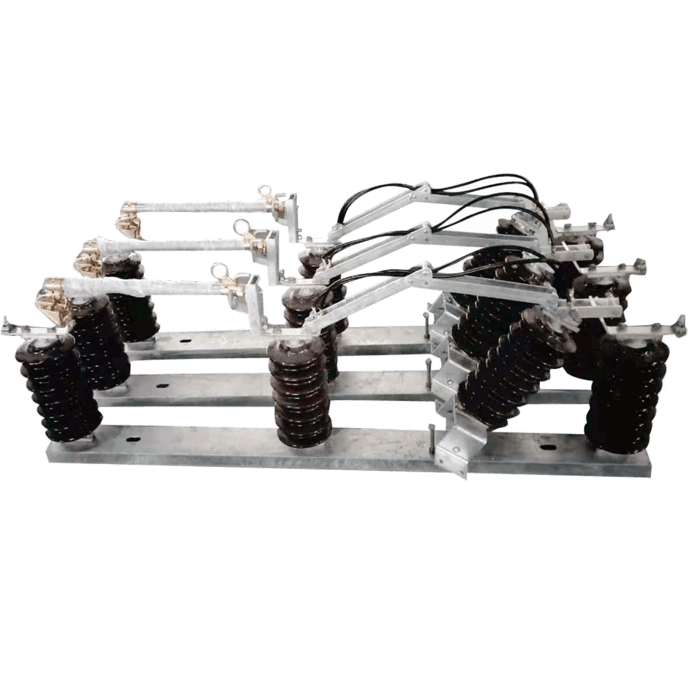

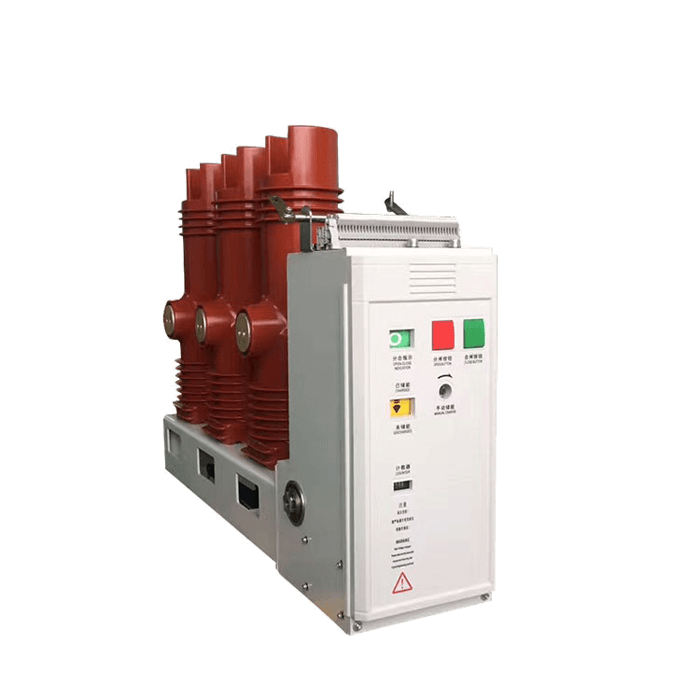

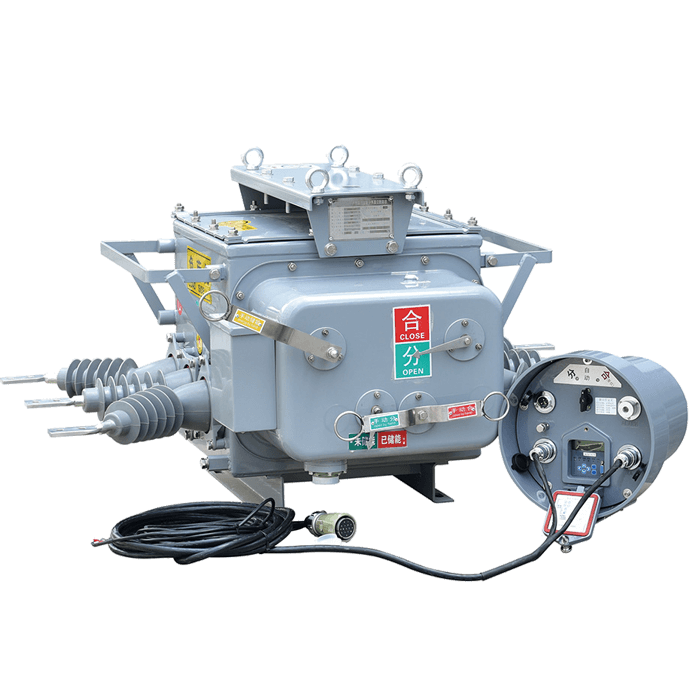

AC high voltage switch-disconnectors are used in indoor or outdoor medium voltage systems with a rated frequency of 50/60 Hz. The load switch is generally composed of an isolation plate, an arc extinguishing chamber and an operating mechanism. The arc chute is made of insulating material, which has the advantages of high dielectric properties and arc resistance.

Among the several switchgears that are widely used in medium voltage distribution systems, they change the grid configuration, isolate faulty components from the grid, etc. A load break switch is an amazing switch. For reasons of analyzing breaking capacity, load break switches with rated voltages up to 52kV must be subjected to various test tasks according to IEC 62271-103.

In advanced economies or highly industrialized societies, maintaining power continuity to consumers is a priority as the way we generate, transmit, and use electricity continues to change. With the goal of integrating into a smart city, the safety of electrical equipment is protected by quickly disconnecting the power supply in the event of leakage current, arc, overcurrent or overvoltage and other fault events, and is handled by switchgear such as isolation switches and circuit breakers. For systems up to 33kV, more expensive circuit breakers are being replaced by load break switches. A load break switch is a switching device used in the voltage range 12 to 36 kV and must have the following functions:

- Interruption current equal to its continuous rated current at system voltage and power factor of normal load

- Designed with sufficient insulation to isolate the circuit in the closed position.

- Interruption of small capacitive and inductive currents critical for disconnecting unloaded overhead lines, transformers, cables, etc.

- Carry the maximum fault current for the time required by the interrupting device to clear the fault.

- Causes terminal failure at rated voltage.

Switching state after breaking test and short-circuit making test:

- After the specified breaking test on a sample, after the test load TDma, the mechanical function of the switch and the insulator shall be in almost the same condition as before the test.

- If one of the following conditions is met, it is deemed to meet the requirements of being able to carry its rated normal current:

- Visual inspection of primary contacts indicates good condition; or if impractical or unsatisfactory,

- The measured resistance is as close as possible to the main contacts and does not increase by more than 20% compared to the resistance measured before the test. A maximum of 10 no-load operations may be performed before the contact resistance is measured, or if the conditions of b) are not met

- Testing at rated thermal maximum current has shown that no thermal runaway has occurred and no temperature and temperature rise limits have been exceeded by monitoring the temperature at the resistance measurement point until stable. No other temperature measurements will be made inside the switchgear during this test. If stabilization cannot be obtained, or the temperature and temperature rise exceed the limits, the condition check fails and the switch is considered to have failed the test task.

JGGY develops load-break switches and other switchgear such as fuses, disconnectors, earthing switches, circuit breakers and arresters.

Ms Miya: sales@jggyelectrical.com

Whatsapp: +86 181 0679 6660